|

MILL BULB TOOL |

Once upon a time, pinball manufacturers used to include, with their new games, a little device to help the operators keep their games looking their best. This device consisted of a wooden stick and a piece of rubber. Sometime the rubber was attached to the stick, sometimes not. In either case, the purpose of this wood/rubber combination was to make it easier to remove lamps from hard-to-reach places. The extractor tools haven't been included with games for many years now, so other techniques have been employed to remove dead or suspect lamps from games. Specialist lamp removal tools made out of rubber or plastic have been available, while a shooter tip can also be used as an impromptu extraction tool if nothing else is available. The problem with these methods is the way they are limited to certain, fixed lamp sizes, and the extra space they need around the lamp so they can slip over the glass bulb. Another way to extract a lamp is with a pair of needle-nose pliers wrapped in electrical tape to them give some grip on the bulb. This is obviously not ideal either. The actual area of contact is limited and, due to the shape of the pliers, all the pressure is concentrated in a small area at the top of the glass, reducing the grip available and increasing the possibility of the bulb shattering. So what's the solution? Mill Amusement thinks this is.

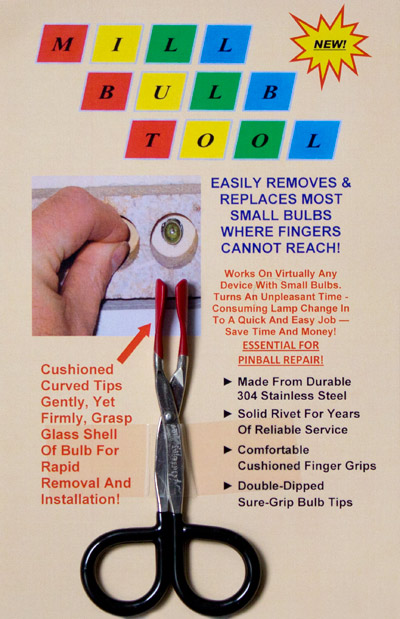

The Mill Bulb Tool is a scissors-like device which clamps onto either side of a lamp's glass bulb, giving you the option to pull a wedge-base lamp out, or push, twist and pull a bayonet-base one. You might recognise the Mill Bulb Tool logo, and Mill Amusement are indeed better known for their Mill Wax pinball playfield wax and cleaner. The Bulb Tool is their new product and Pinball News put it through its paces to see how it's put together and how effective it is.

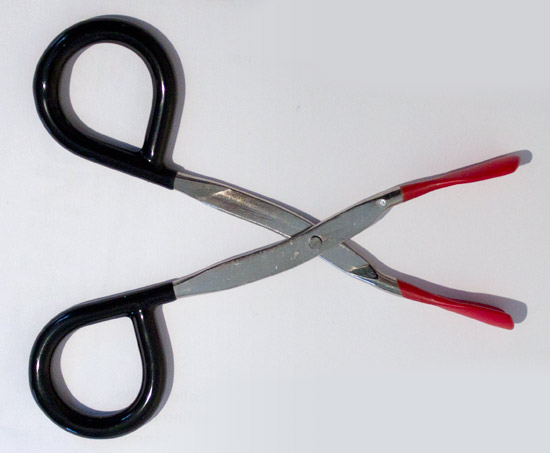

Made from stainless steel, the finger holes are coated in black plastic which gives them a much better level of grip and makes them more comfortable that bare metal would be. The two halves of the tool are identical, so it's equally suited to left or right handed use and it doesn't matter which side you use. The business end is flattened, then curved like a beak and coated in red plastic to provide the grip needed to push, pull and twist the bulb. The arms feel reassuringly solid and don't flex or bend.

When fully closed, the fingers leave a gap of about 6mm, which makes the tool unsuitable for also holding small screws or bolts. That's not its job, of course, but sometimes when fixing a machine you have to use whatever you have to hand. It's the curvature of the arms and that resultant gap which ensures the fingers manage to get a large surface area in contact with the bulb and achieve maximum grip.

Keeping that grip is all-important to ensuring the tool continues to work correctly, so you don't want the plastic coating wearing away or flaking off. We tried scratching it and digging our fingernails into it, to try to split or peel off the coating. We only ended up with damaged fingernails, so it looks like it's built to last.

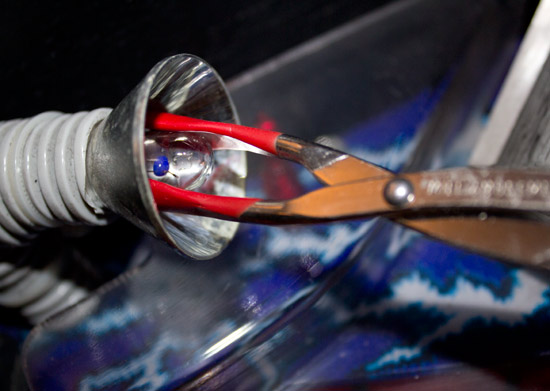

The arms are joined by a solid rivet which seems up to the job and could be replaced fairly easily if it should ever fail. So we put it to use removing lamps from those hard-to-reach places on some of our pinballs' playfields. One of the most annoyingly-tricky places to remove lamps is inside some designs of spot lamps. The one shown below is found on Scared Stiff and - unless you have needle-nose fingers - is a real pain to remove without some kind of extraction tool. We set the Mill Bulb Tool loose on it.

The lamp was in there pretty tightly and it took three attempts to get a good enough grip, but the lamp then pulled out cleanly and without any damage.

You can see in the picture above how the contact surface area is still relatively small due to the shape of the bulb and the way the reflector limits how far down the bulb the tool can get, but the curvature of the fingers as they wrap around the bulb increases that area and makes removal possible. Even a rubber shooter tip or similar specialist tool has a hard time getting enough purchase inside that spot lamp's reflector. The tool can also be used to re-insert lamps into their holders if lack of space or visibility makes it difficult to do by hand.

It's not the most exciting product in the world, but the Mill Bulb Tool does indeed simplify the job of removing those hard-to-reach lamps, while also minimising the risk of damage to either the lamp or its holder. The only reason you might think twice about going straight out and buying one is the price. The recommended retail price of the Mill Bulb Tool is $19.95. The people we asked about the price fell into two camps. There was the "I'm not paying twenty bucks to get a lamp out" school of thinking, and then there was the "only $20 and I'll never struggle to remove a lamp again" camp. In the end it probably comes down to whether you've ever experienced problems removing lamps before or not. We certainly have, and our Mill Bulb Tool has already become a permanent resident in the tool box. We never know when we'll need it, but we'll need it. The Mill Bulb Tool* is available form selected Mill Amusement product retailers. Details and links to sellers can be found on the Mill Amusement website.

© Pinball News 2011 |