| PINBALL EXPO 2008 |

| Date: 1st - 5th October 2008. Welcome to the first full day of Pinball Expo 2008 and it started bright and early at 9am as attendees gather in the lobby of the Westin and got ready to board the fleet of school buses for the trip to the Stern Pinball factory.

The buses turned up on time and they were soon filled.

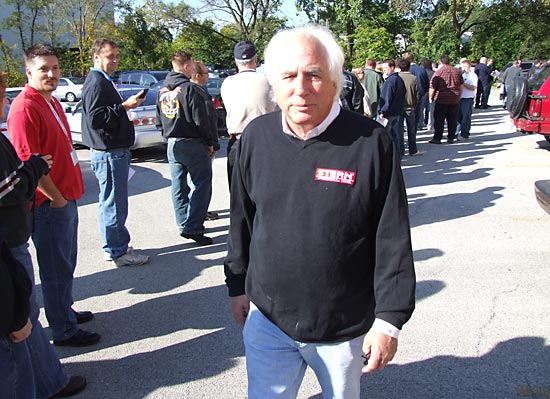

The new location for the show meant the journey to Melrose Park took a little longer than before but it wasn't long before the buses arrived and passengers disembarked and formed an orderly queue in the Stern factory car park.

The line soon grew as all the buses arrived and unloaded while the bright sunny weather made the wait more bearable.

As they stood in line, the visiting group was greeted by Gary Stern.

Vvisitors were given information sheets and admitted into the factory in small groups of 9 or 10.

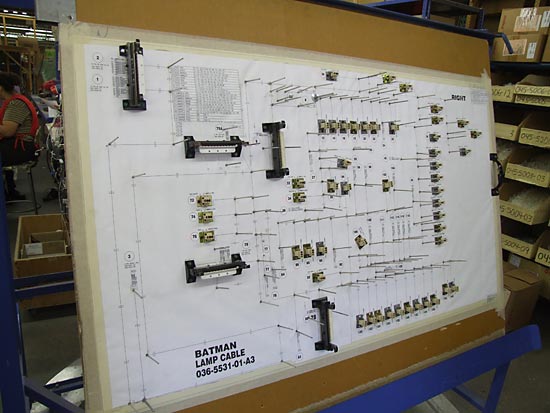

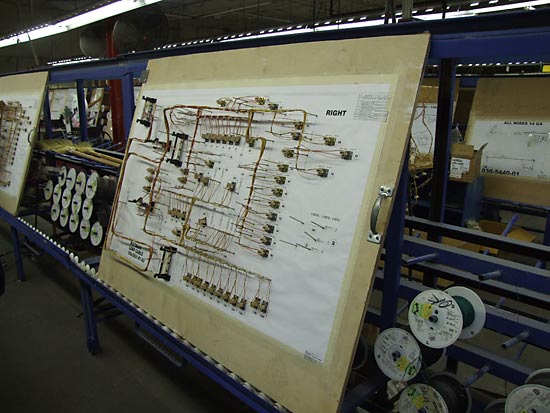

Each group was assigned a tour guide to show them around and explain how the various departments worked. As usual, the tour began in the cabling section. Each large cable is formed by running wires round a wooden sheet. There are pins inserted and a printed guide to indicate the route and the wire colours to use.

As the guide moves down the line, more wires are added.

When all the wires have been added, the loom is then tested to make sure there are no wiring errors.

On an adjacent line, additional cable looms are made for the various playfield switches and the solenoids used in the Batman game.

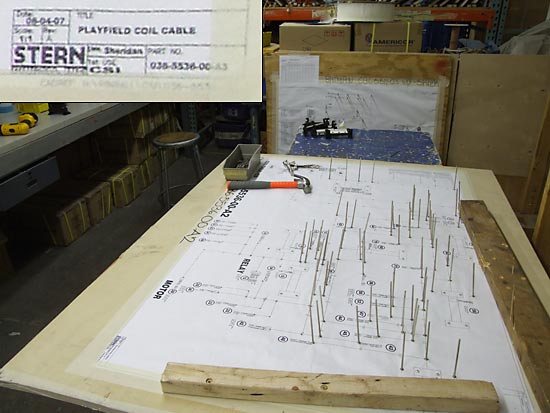

New cable forming guides are made for each model. Here's one for an upcoming game.

Once the cable looms are formed, they need to have the appropriate connectors and terminations fitted so they can connect to the circuit boards and playfield devices. First the pins are attached, then the pins are inserted into the connector housings.

The completed looms are then tested again to make sure the pin arrangements are correct.

The next area is where the playfields are populated with the assorted hardware needed to create a game. The playfields arrive from Churchill Cabinets in racks to be checked and graded.

They arrive as a flat printed sheet, so everything has to be added in the factory. To make sure the components are put in the correct locations, the playfields are perforated by a large press with metal pins on the top and bottom.

With the guide holes made, the playfield is drilled using a metal sheet as a template, before moving down the line to have hardware installed.

T-nuts are hammered in, as are the ball guides. A frightening sight for those who value a pristine playfield.

Once all the standard hardware is fitted to the playfield, it moves down the line to have the assemblies installed. There are separate areas to build each of the assemblies. This Batgadget mini-playfield is constructed from individual component parts.

The completed assembly is then tested to make sure there are no wiring or switch faults.

Other assemblies are constructed at workstations behind the main playfield line.

These assemblies are fitted to the playfield as it moves down the production line.

The playfield is then flipped and more componets are added to the underside.

When it reaches the end of the line, all the components have been fitted and the playfield then enters the test area.

The completed playfields are no use without cabinets and these are populated on a parallel line to the playfields. There were dozens of cabinets and backboxes all around the factory for an assortment of different models such as Family Guy, Spider-Man and Shrek as well as Batman.

The cabinets are fitted with flipper buttons, ground braid, a speaker, a transformer and all the other hardware required as they move down the line.

Meanwhile the computer and driver boards are installed in the backboxes.

Then the cabinet, backbox and tested playfield are combined to produce a complete game.

The game then has the final wiring between the backbox and the cabinet completed and the backbox lamp installed, after which it enters final testing.

Once the game is tested and confirmed as working correctly, the instructions are placed on the playfield and the machine is boxed and ready for shipping.

Batman was on the production line during this factory visit but it is not the only game being built at the moment. A range of games have either just been made or are about to have another run, as shown by the assorted parts scattered around the factory.

The tour ended with visitors being given a couple of promotional plastics before boarding the buses for the trip back to the Westin for the start of the Expo seminars. That brings us to the end of our coverage of the Stern factory tour. We'll be back with much more from Pinball Expo 2008 - including those seminars - very soon.

|